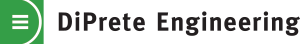

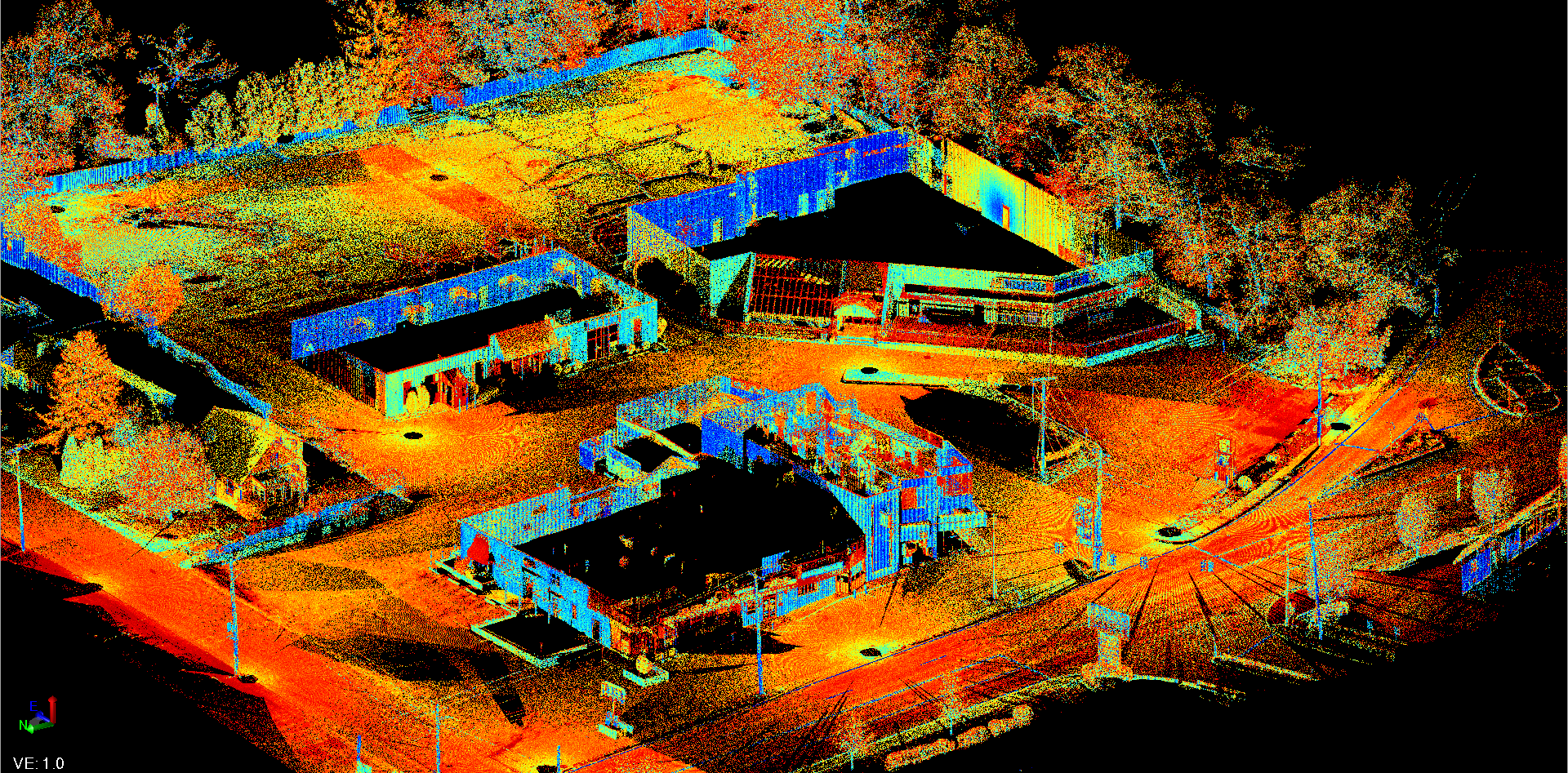

DiPrete Engineering uses innovative 3D laser scanning technology to obtain the most accurate measurements in complicated environments. When looking at existing conditions, the laser scanning instrument collects millions of survey data points, in turn creating a complete 3D model that can then be used for architectural drawings, 3D computer models, and final survey documents. This precision maximizes information while minimizing risk.

3D laser scanning can be used in a range of situations. It is useful when surveying hard-to-reach areas and collecting exact measurements. This technology can help with the construction process and reduce the need for multiple site visits.

The team’s Trimble SX10 Total Station/Laser Scanner allows our survey crew to establish survey grade site control while simultaneously obtaining laser scanning data. This is combined with the latest electronic data collector and office software allowing us to provide our clients any form of survey deliverable that their projects may require.

DiPrete Engineering uses 3D laser scanning for:

- Site as-built surveys

- Structural as-built surveys

- Dam surveys

- Building facade surveys

- Building interior surveys

- Bridge surveys

- Dangerous intersections

- ADA compliance surveys

- Slab flatness surveys